Rotary Table Blasting Machine for Big Metal Parts

This type blast Machine is the right solution for the treatment of large and heavy castings or forgings ranging from 5 to 100 tons, such as marine engines, energy and power generation components and wind towers. The bogie transports the workpiece inside the blast room. The work car is also available with a rotary table (up to 75 T capacity) to rotate the workpiece for optimal blast coverage. Complicated parts which has deep pockets are difficult to be blasted by wheel blast, so a air blasting gun is necessary for thorough cleaning of the parts.

Major features:

? Solution with moving portal for blast wheel arrangement allows for reduced installation space when the blasting demand involves very large workpieces.

? Air blasting stations with guns/nozzles for manual finishing of the workpiece when composite structures are being blasted.

? Double elevators to reduce total height. Cabinet lining in cast plates, manganese steel or rubber according to application.

? Work car has big load capacity, 5 ton to 100 tons. Rotary car has max load to 75 tons, stable and smooth rotation.

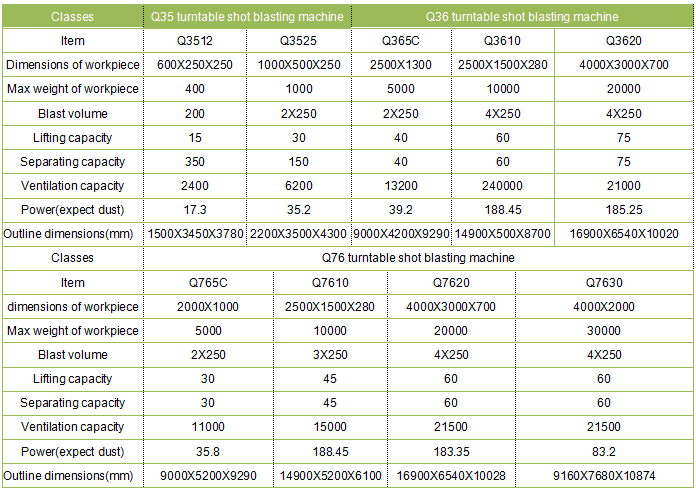

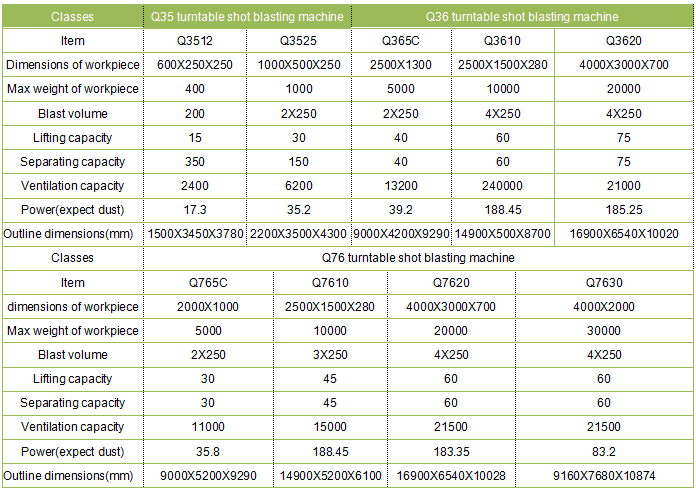

Standard Model and Specification:

No.867 Century Avenue, Huangdao District, Qingdao, China

No.867 Century Avenue, Huangdao District, Qingdao, China 13361277779

13361277779 15908950799

15908950799 No.867 Century Avenue, Huangdao District, Qingdao, China

No.867 Century Avenue, Huangdao District, Qingdao, China 13361277779

13361277779 15908950799

15908950799